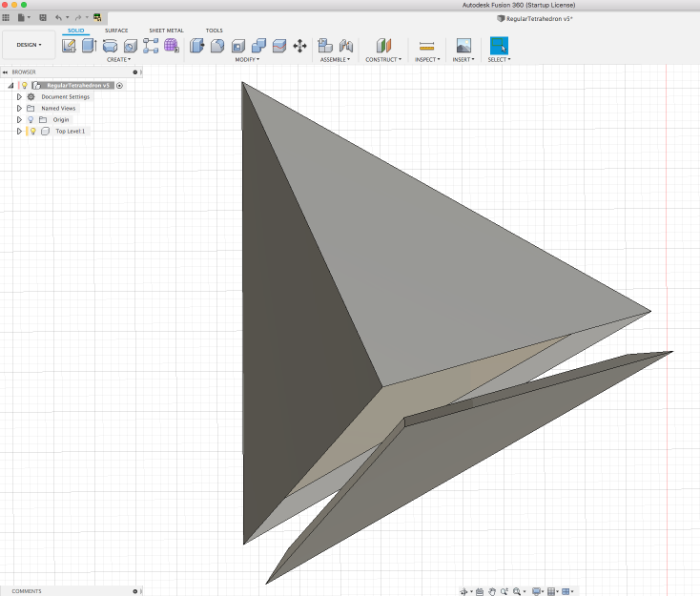

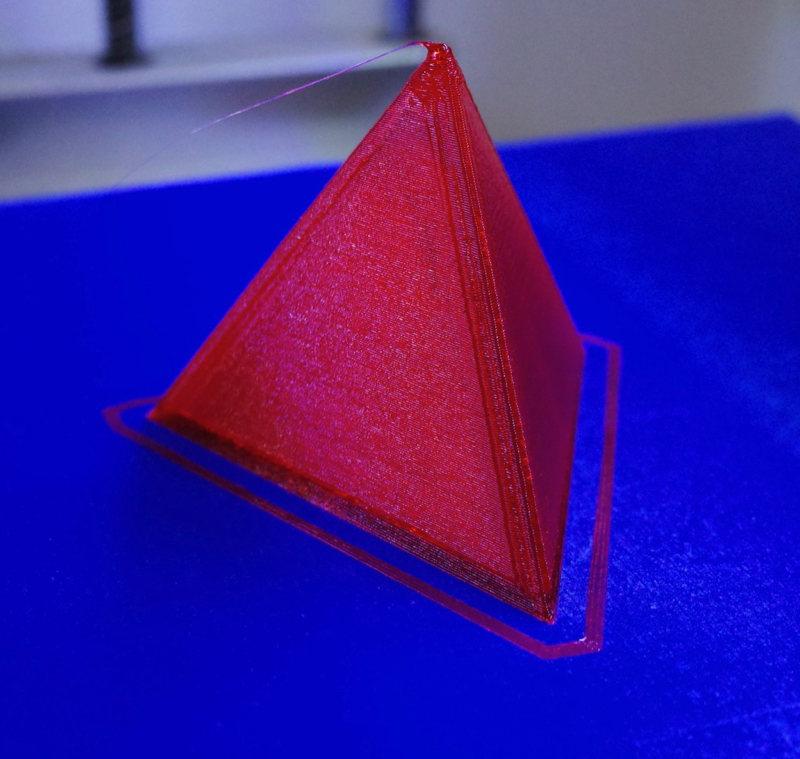

My latest thing has been regular tetrahedrons. My goal is to eventually make these from stainless steel.

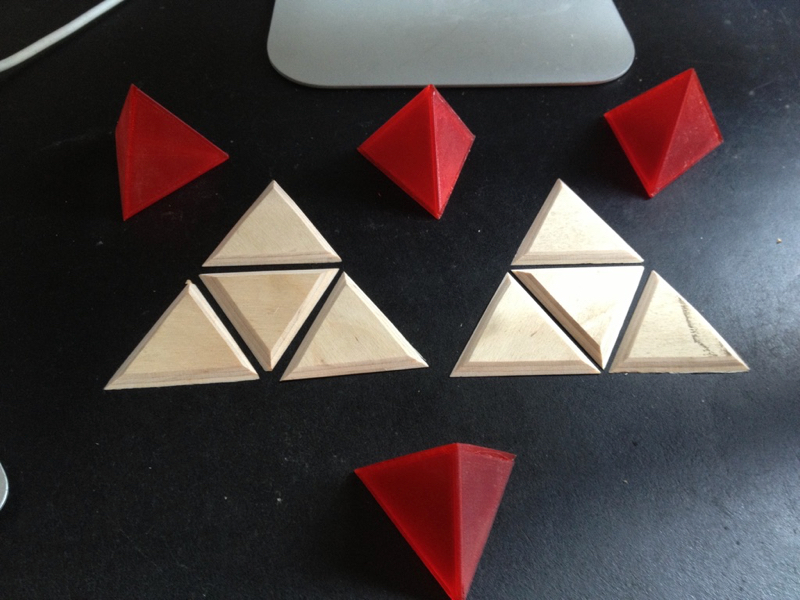

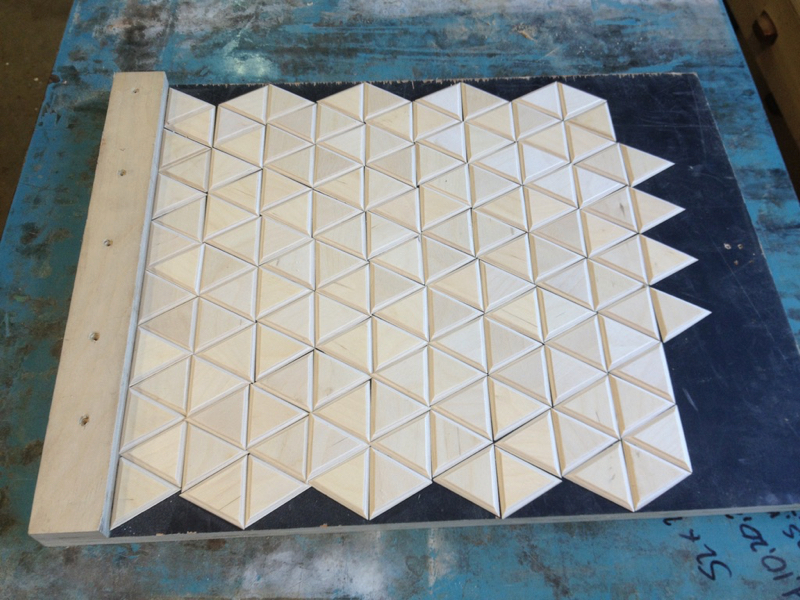

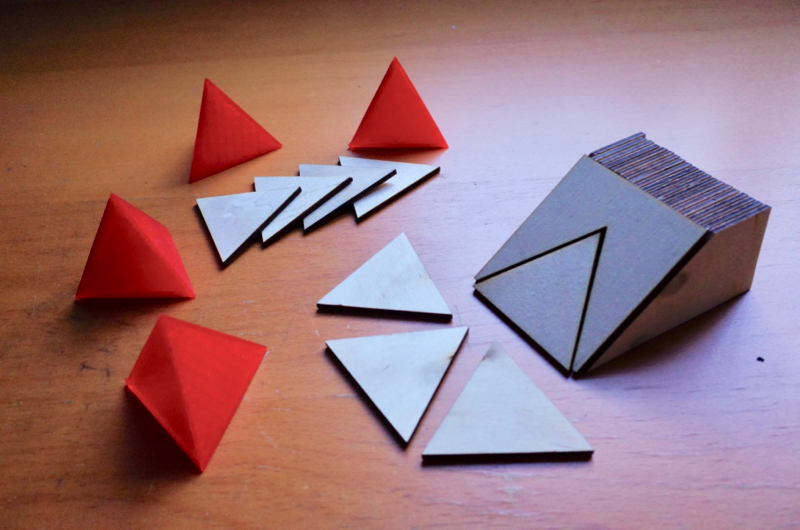

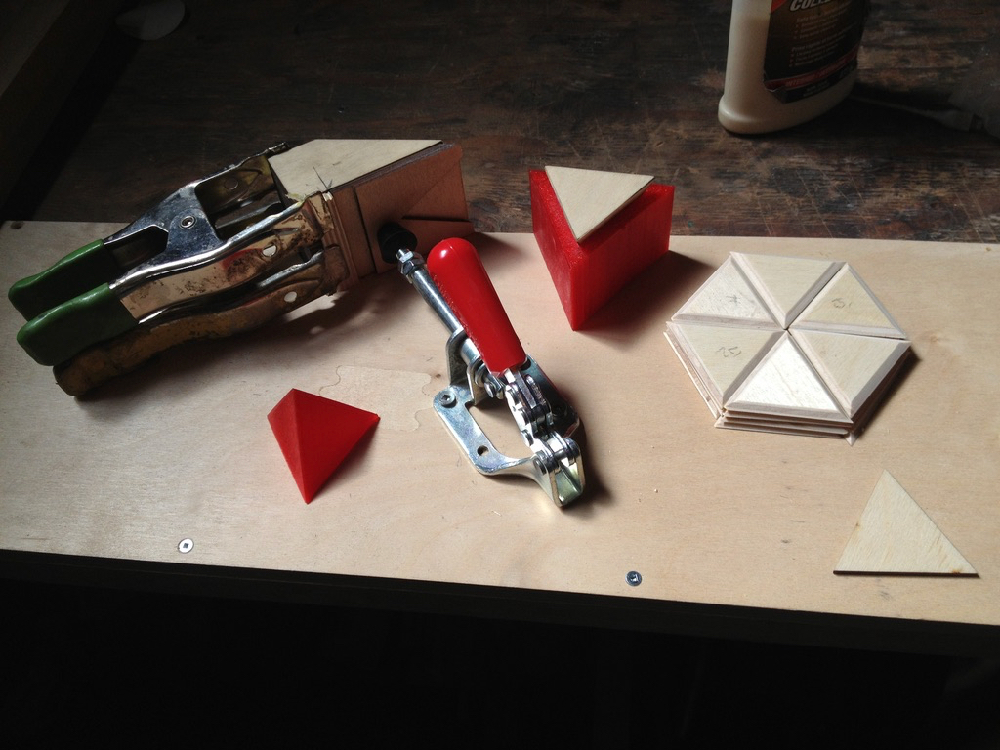

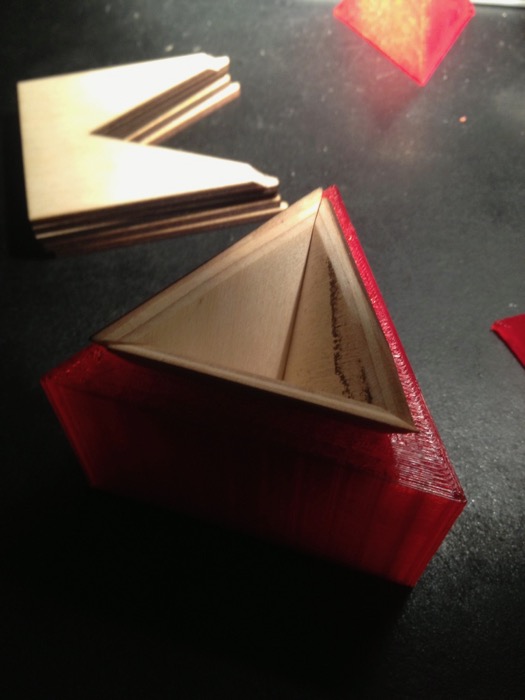

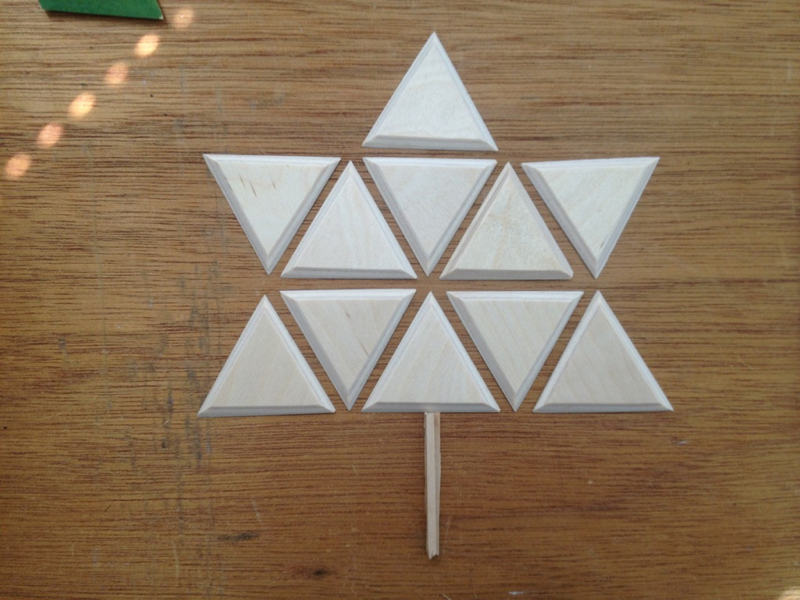

I spent some time creating a 3D model of a regular tetrahedron in Fusion 360. Then I 3D printed a few for sanity check. Next up was to make some of these from 3mm Baltic Birch. Each tetrahedron requires laser cutting 4 equilateral triangles from birch plywood. Then a sanding jig is used to sand each of the 3 edges of each triangle to the correct beveled angle so that each side can be joined the other sides with no gap.

Finally a glue up jig is used to hold the sides easily for assembly. The basic assembly step (laser cutting, bevelling, glue up) of one tetrahedron takes about about 5 minutes per Tetrahedron

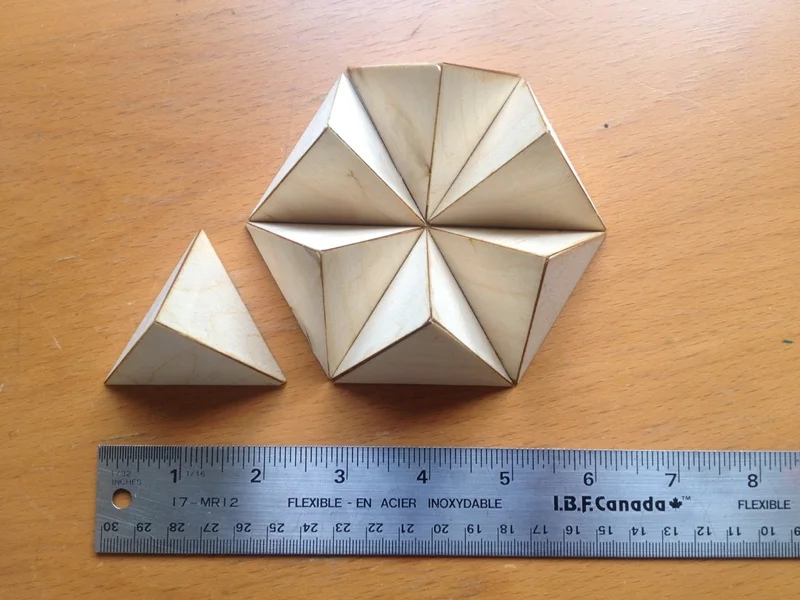

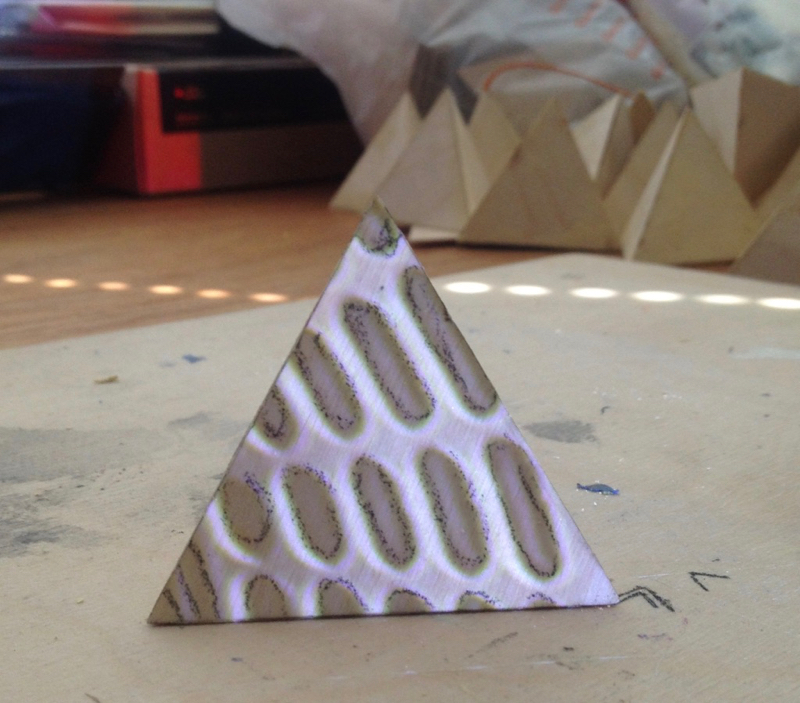

Preparing each tetrahedron to use as an art surface requires additional surface prep time. Any cracks are filled with wood filler, then each side is sanded and all the four surfaces are Gessoed in preparation for painting.

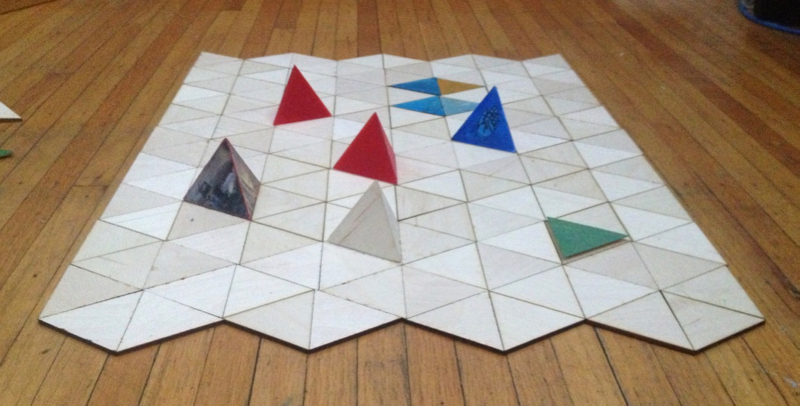

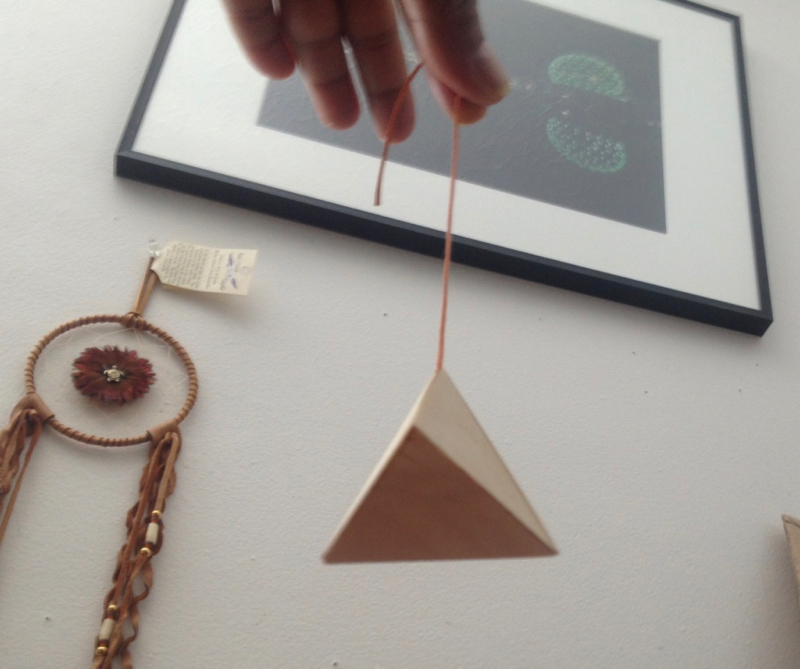

Each Tetrahedron provides four perfect surfaces for creating miniature art pieces. Groupings of tetrahedrons builds larger pieces. The possibilities for repeating patterns are endless in both 2D and 3D spaces. I am looking forward to exploring the possibilities of this space.